Features Reporter

Photo by: Morgan Berry

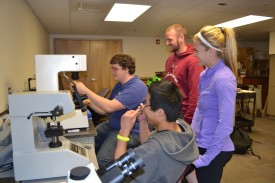

Three miles northwest of campus stands a former manufacturing facility with a wind tunnel, 3D printer, welders, torches and other industrial tools. This is The Archuleta Engineering Center, home to CMU’s Construction management and WCCC’s Machining and Manufacturing programs along with the CMU/CU Boulder Partnership Engineering Program.

“I am actually paid by CU Boulder,” Director of Mechanical Engineering, Tim Brower, said. “We have a partnership with CU Boulder. They are CMU students for two years, but then become CU students and graduate with a CU Boulder degree.”

All classes are offered at CMU, students’ enrollment just changes in the final two years.

“There are three instructors that CMU has hired for the program,” Brower said. “CU professors teach the second two years.”

The ME degree is one of two options that students have for an engineering degree. The other option is a ME Technology degree.

“ME is more theoretical, while Mechanical Engineering Technology is more hands on,” Brower said. “

Brower described the difference as a company engineer who designs a product (the ME degree), and a machinist who makes the product. The MET graduate bridges the gap between the two jobs.

“The students don’t have to choose when they walk on campus,” Brower said. “A lot of schools have engineering and engineering tech, but they are in different colleges. They don’t share resources.”

Some of the largest schools in the nation have hundreds of students in their engineering programs, while the classes here are no larger than 17 students.

“We get to know all of the teachers,” student Isaac Koch said. “We don’t feel like they are trying to weed us out.”

The program is less than five years old and last year saw its first graduating class.

“For the ME degree we had 13, the MET had just two,” Brower said.

Not only is the program growing, but funding and resources for it are as well.

“There are a lot of scholarships out there,” Brower said. “Especially for women. The industry is very supportive, because of the graying of engineering and no crop coming in.”

Even though there are many other countries, like Japan and China producing engineers, some companies cannot accept them. NASA, for example, cannot use foreign engineers because they aren’t able to get a security clearance.

“We have a lot of toys,” Brower said. “Almost as much as kinesiology.”

One such toy is the wind tunnel, which allows testing of drag for cars or planes.

“It can produce winds from zero to 140,” Brower said. “All the students enjoy the wind tunnel.”

These toys allow the students to test the theories they are learning about in class. The wind tunnel, for example, allowed the students to test if winglets, which is a small wing added to the end of plane wings, reduce drag or increase it.

The equipment is also put to use for research.

“I am working on a process that could make aluminum as hard as steel,” senior KC Bretey said. “We are at the point where we are running into problems. It’s not a new process, but only been recently studied, the last 10 years.”

The group that is working on this project is comprised of six students in total, and they are all getting funding from different sponsors from biomedical companies to even gourmet cookware companies.

The program provides a variety of hands on experience and has a prospective job outlook after graduation. According to the United States Bureau of Labor Statistics (BLS) mechanical engineering job growth is expected to rise around 6 percent over the next decade.

jkirk@mavs.coloradomesa.edu

Recent Comments